3D Printing Dominance Is Already Inevitable

We found this article on Forbes magazine today and could not resist sharing it with you all. 3D printing production is still in its infancy, but it is already inevitable. The industrial revolution is NOT the end of the story. But do not think that you can simply sit on the sidelines and watch. The most disruptive innovations do not ask for your permission. But they do demand your participation.

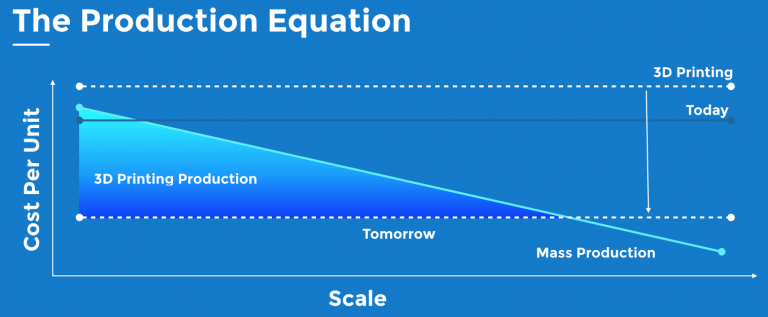

With 3D printing, costs are not tied to the number of units produced, so you are not penalized for producing in small quantities. In the chart below, you see that the line for 3D printing is flat. Would you like to produce only the items needed this month? No problem. How about ten of the exact same object, but produced in ten different locations simultaneously around the world, closest to your customers? Done. Need to customize every single object for every single consumer? 3D printing allows for unlimited flexibility and customization at no additional cost per unit.

Now, since its introduction 20 years ago, the cost of 3D printing production has been quite high relative to conventional scale manufacturing, but costs have been dropping while quality has risen sharply.

The darker blue line represents approximately where we are today, just scratching the surface. But the blue triangle represents the future that leaders around the world are seeing. 3D printing production is still in its infancy, but it is already inevitable. At the same cost and quality, companies will always choose the flexibility of 3D printing over mass production. At the same cost and quality, 3D printing irreversibly overtakes conventional manufacturing as the preferred method of production. And that, my friends, changes everything.

The benefits of 3D printing production are not just limited to flexibility and customization, either. 3D printing not only allows you to customize the design (geometry) of each object, you can also customize the materials used in production. In addition, unlike conventional manufacturing, where added complexity dramatically increases per unit costs – with 3D printing production it does not. In fact, with 3D printing you are now actually able to create complex geometries that can be manufactured in no other way (examples include the new GE jet engine parts highlighted in the previous article). The point of highlighting the advantages of flexible production size is simple: based on this advantage alone, at the same cost and quality as conventional manufacturing, 3D printing has already won.

When will this historic transition begin? It already has – look no farther than Henry Ford’s namesake, the Ford Motor Company, which recently celebrated the production of their 500,000th 3D-printed industrial part.

3D printing production is still in its infancy, but it is already inevitable. The industrial revolution is NOT the end of the story. But do not think that you can simply sit on the sidelines and watch. The most disruptive innovations do not ask for your permission. But they do demand your participation.

© 2022 3ecruit all rights reserved | Privacy Policy | Privacy & Cookie Policy | Powered with 🤍 by Shazamme